Printing your own fabric is a creative and fulfilling way to add a personal touch to your projects. Whether you want to make custom clothing, home décor, or unique gifts, fabric printing allows you to design patterns and colors that are entirely your own. In this step-by-step guide, we’ll walk you through the different methods of fabric printing, the materials you’ll need, and how to achieve professional results from home.

By the end of this guide, you’ll be equipped with the knowledge to experiment with different techniques and create stunning, one-of-a-kind fabric designs.

Table of Contents

Why Print Your Own Fabric?

Printing your own fabric is becoming increasingly popular among crafters and DIY enthusiasts. Here’s why:

- Customization: You can create your own designs and patterns, giving you complete control over the final look of your fabric.

- Creative Freedom: Printing fabric allows you to bring your unique vision to life without being limited by the pre-made fabrics available in stores.

- Cost-Effective: Printing fabric at home can be more affordable than purchasing custom-printed fabric from commercial suppliers.

- Eco-Friendly: You can choose sustainable fabrics and eco-friendly inks to minimize your environmental impact.

Different Methods of Fabric Printing

There are several methods you can use to print fabric at home. Each has its pros and cons, depending on the materials you have available and the level of detail you want in your designs.

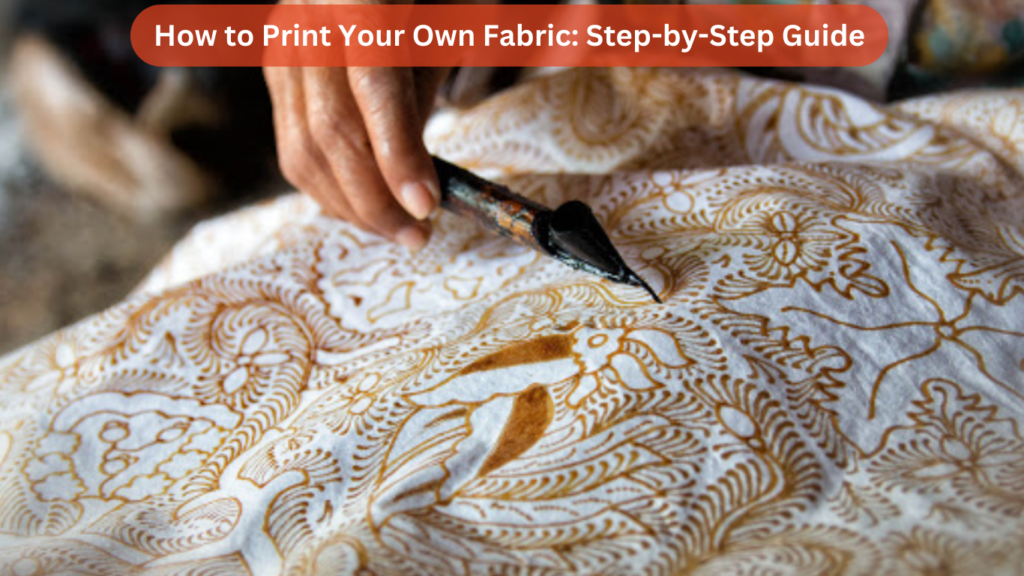

1. Block Printing

Block printing is one of the oldest methods of printing on fabric. It involves carving a design into a block, applying ink or paint to the block, and pressing it onto the fabric. This technique is simple, affordable, and works well for repeating patterns.

2. Screen Printing

Screen printing is a popular choice for creating detailed designs. It involves using a stencil and a mesh screen to apply ink to fabric. While this method requires more materials and setup, it delivers professional-quality results.

3. Sublimation Printing

Sublimation printing transfers designs onto fabric using heat. It requires a sublimation printer, transfer paper, and heat press, making it more equipment-heavy but ideal for printing complex, vibrant designs on polyester fabrics.

4. Digital Fabric Printing

Digital fabric printing is the most advanced method, requiring specialized printers that print directly onto fabric. While this method offers precision and high-quality prints, it can be expensive due to the cost of the printer and ink.

5. Stencil Printing

Stencil printing is another beginner-friendly method. You can create a stencil of your design using paper or plastic, then apply fabric paint through the stencil. This method is great for simple designs and bold shapes.

6. DIY Fabric Transfers

Using transfer paper, you can print your design using a regular inkjet printer and transfer it to fabric using heat. This method is easy and affordable, but the designs may not be as durable as other techniques.

Materials You’ll Need

Before you begin your fabric printing project, make sure you have the following materials:

- Fabric: Choose a fabric that is suitable for printing. Cotton, linen, and polyester are common choices depending on the printing method.

- Fabric Paint or Ink: Select fabric-specific paint or ink that works with your printing method. For example, use fabric ink for screen printing or fabric paint for block and stencil printing.

- Carving Tools (for block printing): These are used to carve out your design on a block or linoleum sheet.

- Screens and Mesh (for screen printing): A fine mesh screen and a squeegee are essential for screen printing.

- Transfer Paper (for DIY fabric transfers): This paper allows you to transfer images printed on an inkjet printer to fabric.

- Stencils (for stencil printing): You can either buy pre-made stencils or make your own using acetate or heavy paper.

- Heat Press/Iron: Used to set ink and paint, ensuring your design remains durable and wash-resistant.

Preparing for Fabric Printing

Step 1: Choose Your Fabric

The first step in any fabric printing project is selecting the right fabric. Cotton is often a preferred choice because it absorbs ink and paint well. However, the fabric you choose will depend on the project and printing method.

- Natural Fabrics: Cotton, linen, and silk are great for most fabric printing methods because they absorb inks and dyes evenly.

- Synthetic Fabrics: Polyester and blends work best with sublimation printing, as the heat-reactive dyes bond well with synthetic fibers.

Step 2: Pre-Wash the Fabric

Always pre-wash your fabric to remove any chemicals or treatments from manufacturing. This step ensures that the ink or paint will adhere properly to the fibers. Wash the fabric without fabric softeners and let it dry completely before printing.

Step-by-Step Guide to Block Printing

Step 1: Design Your Block

For block printing, you’ll need to carve a design into a linoleum block, woodblock, or even a potato for small projects. Sketch your design on paper first, then transfer it to your block. Keep in mind that your print will be a reverse image of the block, so plan accordingly.

Step 2: Carve the Block

Using carving tools, carefully carve away the areas that you don’t want to print. The remaining raised surface will be inked and pressed onto the fabric. Be mindful of details as they’ll directly impact the final design.

Step 3: Apply Fabric Ink

Apply fabric ink or paint to the raised surface of your block using a brayer or paint roller. Ensure an even coating without excessive ink, as too much can cause smudging.

Step 4: Press the Block onto the Fabric

Place the inked block onto your fabric and press firmly to transfer the design. Lift the block carefully to avoid smearing the print. Repeat the process as needed to create a pattern across the fabric.

Step 5: Set the Ink

Once your design is printed, let the ink dry completely. Then, use an iron or heat press to set the ink according to the manufacturer’s instructions. This step ensures the print is permanent and won’t wash out.

Step-by-Step Guide to Screen Printing

Step 1: Prepare the Screen

Stretch the mesh screen tightly over a frame. Next, apply a light-sensitive emulsion to the screen, which will act as the stencil for your design. Let the emulsion dry completely.

Step 2: Create Your Design

Print or draw your design on a transparent sheet. Place the transparency on top of the screen and expose it to light. The light hardens the emulsion, except in areas blocked by your design. Rinse the screen with water to remove the unhardened emulsion, leaving your design on the screen.

Step 3: Apply Ink to the Screen

Position your screen on top of the fabric. Pour fabric ink along one edge of the screen and use a squeegee to pull the ink across the design. Apply consistent pressure to ensure even coverage.

Step 4: Lift the Screen

Carefully lift the screen to reveal your printed design on the fabric. If you’re printing multiple items, repeat the process with each piece of fabric.

Step 5: Set the Ink

After the ink has dried, set it with an iron or heat press to make the print permanent.

Step-by-Step Guide to Sublimation Printing

Step 1: Print Your Design

For sublimation printing, you’ll need a sublimation printer and special sublimation ink. Print your design onto sublimation paper, making sure the image is mirrored so it transfers correctly onto the fabric.

Step 2: Heat Transfer

Place the printed sublimation paper face-down on your fabric. Use a heat press to apply even pressure and high heat (around 375°F) to the paper. The heat will cause the ink to vaporize and bond with the polyester fibers.

Step 3: Remove the Paper

After pressing for 30-60 seconds, remove the paper to reveal the transferred design. Sublimation creates vibrant, long-lasting prints on polyester fabrics.

Tips for Successful Fabric Printing

- Test First: Always test your printing method on a scrap piece of fabric before starting your final project. This helps you gauge the ink’s behavior and the fabric’s absorbency.

- Keep the Fabric Flat: To avoid wrinkles or uneven printing, make sure your fabric is flat and smooth. Use fabric weights or tape to hold it in place if necessary.

- Use High-Quality Materials: Invest in good-quality fabric ink and paint, as they will produce more durable and vivid results.

- Practice Patience: Allow adequate drying time between layers of ink or paint. Rushing the process can lead to smudging and uneven prints.

- Proper Ventilation: If you’re using fabric inks, especially those for screen printing or sublimation, ensure you work in a well-ventilated area to avoid inhaling fumes.

FAQs

1. Can I print on any fabric?

Yes, but different fabrics react differently to printing methods. Natural fabrics like cotton and linen work best with most printing techniques, while synthetics like polyester are ideal for sublimation printing.

2. How do I make sure the ink stays on the fabric?

Always heat set your ink or paint according to the manufacturer’s instructions. This usually involves ironing or using a heat press to ensure the print remains permanent after washing.

3. Can I print multiple colors?

Yes! For block printing and screen printing, you can layer different colors by allowing each layer to dry before applying the next. Sublimation and digital printing allow for complex, multi-color designs.

4. How do I clean printed fabric?

Printed fabrics should be washed in cold water with a gentle detergent.

Conclusion

In conclusion, printing your own fabric is an exciting way to express your creativity and personalize your projects. Whether you opt for block printing, screen printing, sublimation, or digital fabric printing, each method offers unique benefits and endless possibilities. With the right materials, a little practice, and attention to detail, you can achieve professional-quality results right from the comfort of your home.

By exploring different techniques and experimenting with designs, you not only enhance your crafting skills but also create one-of-a-kind textiles that reflect your personal style. Remember to take the time to test your methods, invest in quality materials, and follow the proper care instructions to ensure your printed fabrics last.

As you embark on your fabric printing journey, let your imagination run wild. From custom clothing to unique home décor and heartfelt gifts, the possibilities are truly limitless. So gather your supplies, unleash your creativity, and enjoy the satisfying process of bringing your fabric designs to life. Happy crafting!